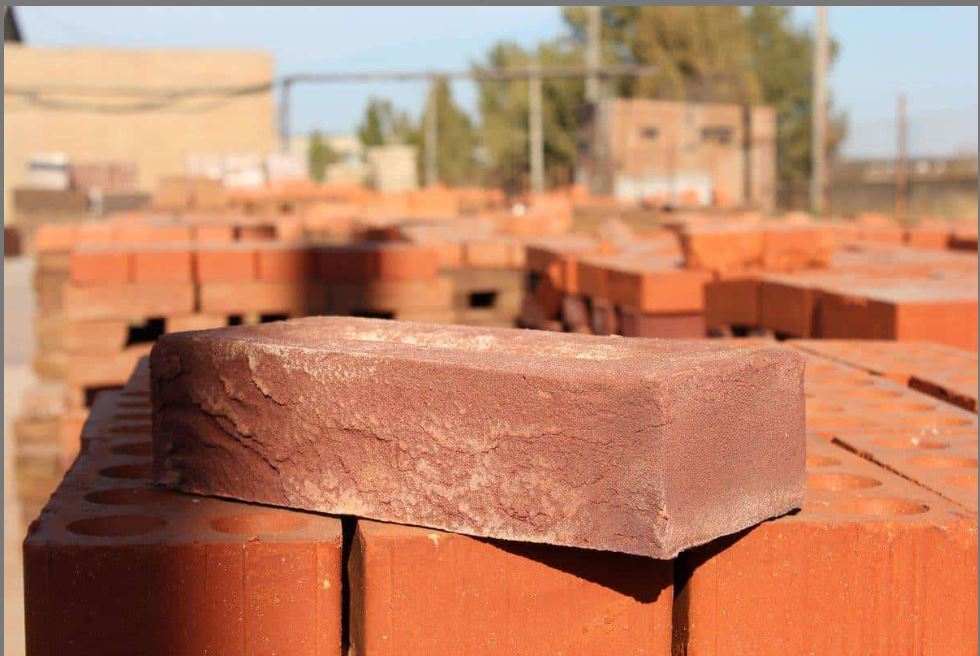

Table molded bricks in mysore

Best Table Molded Bricks in Mysore Today

Table of Contents

- Introduction: Table Molded Bricks in Mysore

- Why Choose Table Molded Bricks? Benefits & Features

- Types of Table Molded Bricks We Supply

- First Class Table Molded Bricks

- Specialty & Decorative Table Molded Bricks

- Manufacturing & Quality Standards

- Our Supply Chain: Foundation to Finish

- How to Choose the Right Table Molded Brick

- External Resources & Further Reading

- Conclusion & Contact Info

1. Introduction: Table Molded Bricks in Mysore

Table Molded Bricks in Mysore are a trusted staple for builders throughout the city. At MCMS constrcution material supply, based in Mysore, we specialize in supplying Table Molded Bricks in Mysore and a full range of construction materials—from foundation to finish. Whether you’re constructing a new home or renovating an existing structure, our bricks provide the strength and aesthetic appeal you need.

2. Why Choose Table Molded Bricks? Benefits & Features

Table molded bricks—made using a five-sided mold on a table rather than the ground—offer superior quality and consistency.

Key Advantages:

- Economical yet durable, with good compressive strength for standard construction needs mcmsindia.com

- Excellent insulation, helping maintain steady interior temperature mcmsindia.com

- Sharp, uniform edges and clean texture thanks to low moisture molding mcmsindia.com

- Lighter environmental footprint, reusable, recyclable, and easy to demolish if needed mcmsindia.com

- Strong fire resistance; ideal for long-lasting structures mcmsindia.com

3. Types of Table Molded Bricks We Supply

First Class Table Molded Bricks

These premium bricks are table molded with sharp edges, smooth surfaces, and standard dimensions. With water absorption below ~15% and compressive strength exceeding ~10.5 N/mm² (≈105 kg/cm²), they’re perfect for permanent, load-bearing structures, walls, and facades mcmsindia.com

Specialty & Decorative Table Molded Bricks

- Perforated Bricks: Lightweight, with holes for ventilation—ideal for non-load-bearing walls and partitions mcmsindia.com

- Hollow Bricks: Offer better insulation (heat/sound), with cavities inside the brick body mcmsindia.com

- Bull-nosed, Circular, and Cornice Bricks: Custom-shaped to enhance aesthetics and meet decorative needs—perfect for curves, rounded edges, or architectural accents mcmsindia.com

4. Manufacturing & Quality Standards

Manufacturing Process

Table molding starts with tempered clay placed into a five-sided mold on a raised table (approx. 2m x 1m x 0.7m). After filling, excess clay is removed, and the mold is lifted to leave a shaped brick. Each brick includes a frog (10–20 mm depression) to hold mortar and optionally bear a brand mark mcmsindia.com

Drying happens naturally (sun or shade), followed by high-temperature kiln firing to enhance hardness and durability mcmsindia.com

Quality Checks

- Sound Test: Two bricks tapped together should produce a clear ringing sound mcmsindia.com

- Physically: Should have uniform color, sharp edges, and be free from chips or warping mcmsindia.com

- Strength & Absorption: Compressive strength <105 kg/cm²; water absorption under 20% mcmsindia.com

- Standards: Compressive strength typically aligns with IS 1077–1992 specs mcmsindia.com

5. Our Supply Chain: Foundation to Finish

At MCMS Construction material supply , we ensure:

- Timely Delivery across Mysore and surrounding regions.

- Variety in Form & Function: From first-class table molded to decorative and performance-focused variants.

- One-Stop-Shop Convenience: Not just bricks—we offer a complete range of construction materials from foundation to finish.

- Consistent Quality & Support: Whether it’s strength, finish, or custom demand—we’ve got you covered.

6. How to Choose the Right Table Molded Bricks

| Project Type | Recommended Brick Type |

|---|---|

| Structural, load-bearing walls | First Class Table Molded Bricks |

| Partition walls | Perforated Table Molded Bricks |

| Thermal/sound insulation | Hollow Table Molded Bricks |

| Curved or architectural details | Bull-nosed, circular, cornice bricks |

Also consider color uniformity and sound quality when selecting for quality assurance.

7. External Resources & Further Reading

- Examples of general brick types and uses (Burnt clay, fly ash, sand lime, etc.) mcmsindia.com

- Detailed manufacturing process descriptions for context and comparison mcmsindia.com

- Visual comparisons of first-class vs other brick types and their strength characteristics mcmsindia.com

8. Conclusion & Contact Info

To wrap up, Table Molded Bricks in Mysore—especially our first-class variants—are the ideal choice for long-lasting, structurally sound, and visually appealing construction. At MCMS Construction materil supply, we offer variety, quality, and reliability, backed by full-spectrum materials for your project needs.

For inquiries or quotes on Table Molded Bricks in Mysore, give us a call at 9686608901 or visit our office at Kuvempunagar jodi road. Let’s build something strong—together.

we will never break your trust like others do