Sand and Red Bricks for construction in Mysore

Sand and Red Bricks for Construction in Mysore | Supplier of All Construction Materials

Table of Contents

- Introduction: Sand and Red Bricks for Construction in Mysore

- Why Sand and Red Bricks are Crucial in Cons truction

- Types of Sand We Supply in Mysore

- River Sand

- M‑Sand (Manufactured Sand)

- Plastering Sand

- Course Sand / Concrete Sand

- Filling Sand

- Types of Red Bricks We Supply in Mysore

- First Class / Class 1 Red Bricks

- Wire‑Cut Red Bricks

- Table‑Mould Red Bricks

- Hollow & Perforated Red Bricks

- Over‑burnt / Under‑burnt / Chatka Bricks

- Soil Bricks / Adobe Bricks

- How to Choose the Right Sand and Red Bricks for Your Project

- Matching Load Requirements

- Durability, Weather Resistance, Local Climate

- Finish & Aesthetics

- Cost vs Quality Trade‑offs

- Our Supply Capacity & Quality Assurance

- Installation Tips & Best Practices

- Final Thoughts

1. Introduction: Sand and Red Bricks for Construction in Mysore

Sand and Red Bricks for construction in Mysore are among the most foundational materials in any building project. Whether you are building a home, commercial structure, or doing renovation, choosing the right kind of sand and the right kind of red brick can impact durability, finish, cost, and structural strength. As a leading construction materials supplier in Mysore, we supply every kind of sand and red brick you may need — from foundation to finish.

2. Why Sand and Red Bricks are Crucial in Construction

Using proper sand and red bricks for construction in Mysore matters because:

- Load bearing & strength: Red bricks are used in load‑bearing walls, plinths, beams, etc. Poor quality bricks lead to cracks or even failures.

- Workability and finish: Sand of proper grade ensures mortar binds well, surfaces finish smoothly, plaster adheres, and joints are clean.

- Durability in climate: Mysore has a tropical climate with heavy rain and some temperature variation. Materials should resist moisture absorption and weathering.

- Cost efficiency: Using the right sand and second or third class bricks where appropriate can save cost, but for structural parts only high‑rated materials should be used.

3. Types of Sand We Supply in Mysore

We supply multiple types of sand to suit different stages of construction:

3.1 River Sand

Natural sand taken from riverbeds. Very good for general concrete work, where texture and finer gradation matter. Has good particle shape and bit of rounded edges, which often helps workability.

3.2 M‑Sand (Manufactured Sand)

Crushed stone sand, processed, washed, graded. Excellent substitute for river sand where natural sand is scarce. Provides consistent quality. Good for concrete, plastering, flooring etc. (As per local market trends in Mysore, M‑Sand is increasingly preferred.) MCMS India

3.3 Plastering Sand

Finer fractions of sand, washed and sieved more carefully so mortar and plaster finishes are smooth. Less coarse particles. Ideal for internal plastering, external plaster finishing, ceiling plaster etc.

3.4 Coarse / Concrete Sand

Larger particle size sand used in concrete mix, brickwork mortar, base for flooring, foundations. Needs to meet certain gradation for strength and compaction.

3.5 Filling Sand

Rougher sand or waste sand used for filling, leveling ground before slab, backfilling. It may be cheaper grade, but still clean (free of large stones, organic matter).

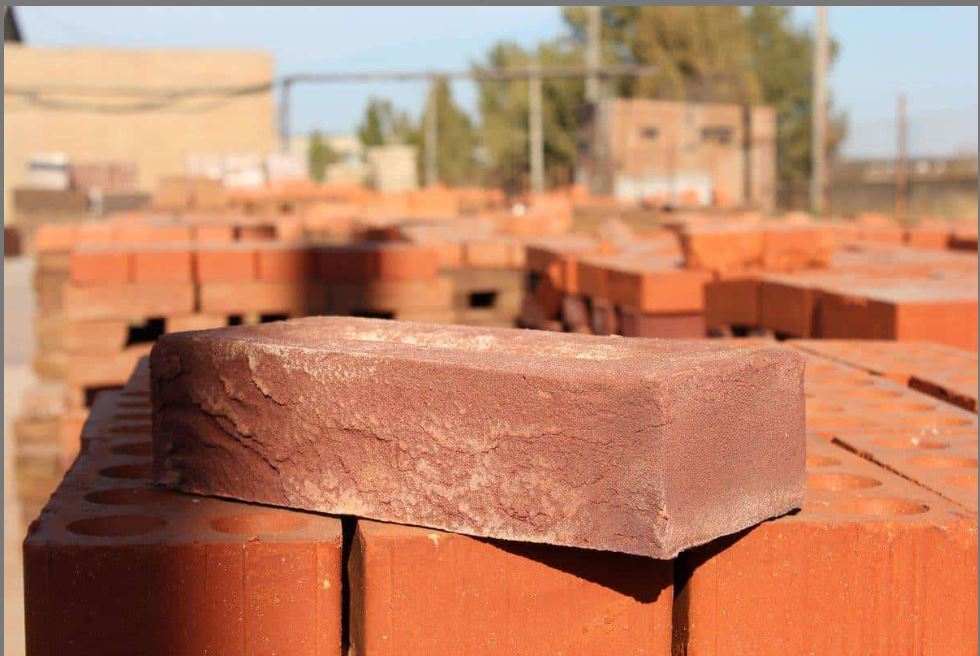

4. Types of Red Bricks We Supply in Mysore

We supply all types of red bricks for construction in Mysore, catering to different strengths, sizes, shapes, and finishes.

4.1 First Class / Class‑1 Red Bricks

Best quality clay bricks, well burnt, uniform shape, smooth faces, low porosity. Used in load‑bearing walls, structural columns. Often used for visible walls or exteriors where durability and strength matter.

4.2 Wire‑Cut Red Bricks

Machine‑made bricks using wire cutting of extruded clay, giving precise dimensions. Good surface finish. Suitable for visible walls, facades, modern architecture. More uniform and less wastage.

4.3 Table‑Mould Red Bricks

Handmade bricks moulded in table moulds. Slight texture, traditional look, slight irregularities. Good for rustic appearances, traditional style constructions, boundary walls or decorative finishing.

4.4 Hollow & Perforated Red Bricks

Bricks with holes or cavities. Lighter, better thermal insulation, faster to lay, less material required. Useful in non‑load bearing walls, partition walls. Must ensure quality to avoid breakage.

4.5 Over‑Burnt / Under‑Burnt / “Chatka” Bricks

- Over‑burnt bricks: too dark, brittle, may shatter; generally not recommended for structural work.

- Under‑burnt bricks: soft, may absorb water too much, weak.

- Chatka bricks: sometimes refers to over‑burnt or lower quality bricks; used sometimes for fill or non‑visible parts.

4.6 Soil Bricks / Adobe Bricks

Made from local soil, often mixed with minimal additives. Eco‑friendly, good for insulation. Usually sun‑dried or minimally kiln burnt. Best in suitable climate zones. For non‑critical structural loads or as partition or infill.

5. How to Choose the Right Sand and Red Bricks for Your Project

When deciding on sand and red bricks for construction in Mysore, consider:

5.1 Matching Load Requirements

For foundations, ground floor, and structural walls, always use first‑class or high quality bricks plus concrete or coarse sand. For partition walls or non‑load bearing, hollow or lighter bricks may suffice.

5.2 Durability, Weather Resistance, Local Climate

Bricks should be well burnt (uniform colour, hardness). Less porosity helps resist rain damage. Sand must be free of clay lumps and organic content which cause shrinkage, dampness.

5.3 Finish & Aesthetics

If the wall is going to be visible without plaster, wire‑cut or table‑mould bricks are better. Plastering sand should produce smooth surfaces. Color and texture of the brick matters for façade.

5.4 Cost vs Quality Trade‑offs

Using the highest grade everywhere may overrun budget. It is better to use high‑grade materials in structural/visible portions, and economy grade in non‑visible or filler parts — without compromising safety.

6. Our Supply Capacity & Quality Assurance

- We source clay red bricks from reputed kilns that meet the required compressive strength and water absorption standards.

- Sand is graded and washed. We test sand for silt content, gradation, and cleanliness.

- We deliver across Mysore and nearby areas. We handle bulk orders & small orders.

- Every brick batch is inspected for shape, uniformity, hardness.

- Our sands are supplied ensuring consistent particle size, cleanliness to avoid defects in concrete or plaster.

7. Installation Tips & Best Practices

- Bricks: Soak bricks before use to reduce suction. Mortar mixing in right ratio (for example cement:sand = 1:6 for masonry etc.). Proper curing of brickwork (moisture keeping) to avoid cracks.

- Sand: Use only clean sand; wash if needed. Use correct mix proportions. For plaster, finer grading reduces plaster thickness and improves finish.

- Ensure mortar joints are uniform. Avoid too much water in mortar.

- Quality check: Drop test brick — if hard sound = good; check edges, corners are square.

8. Final Thoughts

When you choose Sand and Red Bricks for construction in Mysore, what matters most is quality, suitability, and cost effectiveness. As your trusted local supplier, we make sure you get the right sand, the right brick, delivered on time, so your building stands strong, looks good, and delivers value.

Contact us today to discuss your project. Whether it’s foundation work, walls, plaster, or finishing touches — we have the right sand & red bricks for each stage.

We will never break your trust like others do