Sand & Aggregates in Mysore

Sand & Aggregates in Mysore – We worth your trust

Welcome to our comprehensive guide on Sand & Aggregates in Mysore. Whether you’re laying the foundation of a new building, constructing a driveway, or finishing interior work, choosing the right sand and aggregates matters. As a full-service construction materials supplier in Mysore covering everything from foundation to finish, we are here to support your project every step of the way.

Table of Contents

- What are Sand & Aggregates?

- Why choosing the right Sand & Aggregates in Mysore matters

- Types of Sand we supply

- Pit Sand / River Sand

- M-Sand (Manufactured Sand)

- Plastering Sand / Fine Sand

- Fill Sand / Utility Sand

- Types of Aggregates we supply

- Coarse Aggregates (10 mm, 20 mm, 40 mm etc.)

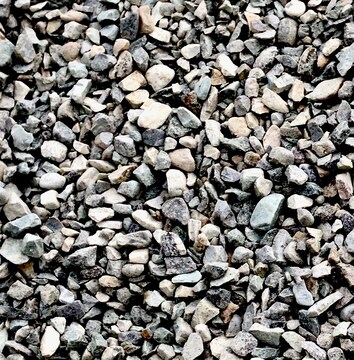

- Gravel / Crushed Stone

- Washed stone dust / Fines

- Special purpose aggregates

- How we at MCMS Construction Material Supply operate in Mysore – supply, delivery, quality control

- How to select the right Sand & Aggregates for your project in Mysore

- FAQs about Sand & Aggregates in Mysore

- Conclusion

1. What are Sand & Aggregates?

Sand & Aggregates in Mysore refers to the raw materials used in construction for mixing concrete, mortar, foundations, flooring, finishing, and so on.

- “Sand” is typically the fine-aggregate component (particles generally less than 4.75 mm).

- “Aggregates” broadly refer to coarse materials (gravel, crushed stone, rock fragments) that occupy a large volume in concrete and support structural strength. Using the correct mix of sand and aggregates ensures strength, durability and workability of construction.

2. Why choosing the right Sand & Aggregates in Mysore matters

In the Mysore region, construction conditions (soil type, climate, availability of materials) demand that you pick quality sand and aggregates. When you use sub-standard materials you risk:

- Poor concrete strength

- Cracks, shrinkage, or uneven settlement

- Higher maintenance or repair cost

By working with a trusted supplier who stocks the full range – from foundation to finish – you ensure that your project flows smoothly and meets quality standards.

3. Types of Sand we supply

Here are the various sands we supply under the banner of Sand & Aggregates in Mysore, and how they are used:

3.1 Pit Sand / River Sand

We supply natural sands sourced responsibly which are ideal for general construction work. Often used for brickwork, blockwork, and concrete casting. Pit sand has coarse particles and good bonding property.

Use-cases: foundation casting, slabs, block masonry.

3.2 M-Sand (Manufactured Sand)

M-Sand is gaining popularity as a substitute for river sand – especially when natural sand sources are limited. It is produced by crushing hard granite or rock into fine particles, and is often more consistent and eco-friendly.

Use-cases: concrete mix, plaster work, where uniform grading is needed.

3.3 Plastering Sand / Fine Sand

For smooth finishes, plastering work and internal mortars, we supply fine-grained sand. The particle size is smaller and provides a good finish and workability.

Use-cases: wall plastering, smooth floor screeds, internal finisher work.

3.4 Fill Sand / Utility Sand

For back-filling, leveling, landscaping, and plumbing trenches, we supply utility sands with suitable grading and compaction properties. Some may not be suitable for high strength structural concrete but perfect for non-structural or ancillary works.

Use-cases: under slabs, leveling ground, bedding for pipes, landscaping fill.

4. Types of Aggregates we supply

Under our “Sand & Aggregates in Mysore” offering, we cover a wide range of aggregate types as well:

4.1 Coarse Aggregates (10 mm, 20 mm, 40 mm etc.)

We stock crushed stone aggregates of various sizes – 10 mm, 20 mm, 40 mm – that are used in concrete mixes, road bases, foundation bases, and more. As per local listings in Mysore you’ll see these sizes widely used.

Use-cases: structural concrete, footings, foundations, driveways.

4.2 Gravel / Crushed Stone

Natural gravel (rounded) or mechanically crushed stone (angular) are part of our supply chain. These serve as the backbone of many concrete mixes because they provide the bulk and load-bearing frame.

Use-cases: road base, sub-bases, general concrete structural work.

4.3 Washed Stone Dust / Fines

Stone dust and fines are results of crushing operations but when properly washed and graded they serve as important components: for filling, bedding, leveling and sometimes as substitute fine aggregate under controlled conditions.

Use-cases: pipe bedding, leveling, non-structural fill, cost-effective base.

4.4 Special-Purpose Aggregates

Beyond standard aggregates, we also supply specialty materials when required: e.g., lightweight aggregates, recycled aggregates, slag aggregates (on request) for specific applications.

Use-cases: lightweight concrete, industrial flooring, special-purpose structural elements.

5. How we at MCMS Construction Material Supply operate in Mysore – supply, delivery, quality control

Being a one-stop supplier of all construction materials from foundation to finish in Mysore, here’s how we serve you:

- Wide inventory: We keep multiple types and sizes of sand and aggregates – as listed above – so you can pick exactly what matches your project.

- Quality assurance: We source from trusted quarries, ensure grading, washing (if required), and check for unwanted fines, silt or clay content – which affect concrete performance. For example, materials passing the 75 µm sieve are considered fines/clay and need special attention.

- Delivery in and around Mysore: We provide timely logistics, so your site is not delayed waiting for material.

- Technical assistance: We guide which sand & aggregates you need for your specific application – whether it’s slab casting, block work, plastering, or landscaping.

- Full-service offering: As a supplier of every construction material from foundation to finish, we mean you can rely on us for not just sand & aggregates, but cement, steel, bricks, finishing materials and more (internally linking within your site).

- Internal link example: See our page on [Bricks & Blocks in Mysore] (link to your internal service page) for masonry components.

- Internal link example: For finishing materials, check [Flooring & Tiles Supply in Mysore] (link to internal).

- Competitive pricing & transparency: We provide quotes based on quantity, delivery schedule, and material grade – no hidden costs.

6. How to select the right Sand & Aggregates for your project in Mysore

Choosing the correct material helps both cost and durability. Here are tips:

- Match material size & use case: For load-bearing concrete use aggregates like 20 mm or 40 mm; for plastering use fine sand.

- Grading & cleanliness matter: Sand with excessive silt/clay reduces bonding; aggregates must be well-graded to avoid voids.

- Source reliability: Make sure your supplier (in Mysore) has consistent inventory and quality – this avoids delays and rejects.

- Consider local conditions: In Mysore, the climate and soil may require materials that meet local structural/weathering demands.

- Cost vs quality trade-off: Cheaper material may save cost upfront but can increase maintenance/repair later.

- Full-service supplier advantage: When you source all materials from one vendor, logistics get simpler and coordination improves.

7. FAQs about Sand & Aggregates in Mysore

Q. What is the difference between natural sand and M-Sand?

A. Natural sand (river or pit sand) is obtained by mining and has smoother particles; M-Sand is manufactured by crushing hard rock, giving angular particles and often more consistency.

Q. What aggregate size should I choose for foundation concrete?

A. Commonly 20 mm or 40 mm coarse aggregate is used for foundation concrete in Mysore. The exact size depends on mix design and structural requirements.

Q. How do I know the sand or aggregate is good quality?

A. Check for: proper particle size distribution, absence of excessive fines/silt, washed material (if required), angular/crushed stone (for strength), supplier certification.

Q. Can I use the same sand for both plastering and concrete?

A. It’s possible but not ideal. Plastering sand is finer and more workable, while concrete sand/aggregate mix requires a different grading for strength. Custom-selecting is better.

Q. Do you deliver across Mysore region?

Yes—we cover Mysore city and surrounding areas, ensuring timely supply of Sand & Aggregates in Mysore including remote sites.

8. Conclusion

When you’re planning any construction work in Mysore—from foundation to finish—selecting the correct Sand & Aggregates in Mysore is foundational to success. Our service offers a full spectrum of sand (pit sand, M-Sand, fine sand, fill sand) and aggregates (various sizes of crushed stone, gravel, stone dust, special purpose) all under one roof, with quality assurance, delivery reliability, and technical support.

If you’re ready to get started, contact us today for a quote. Let us supply the right materials so you can focus on building with confidence.

We will never break your trust like others do