Bricks & Sand in mysore

Bricks & Sand in Mysore – Premium Construction Materials Supplier

Bricks & Sand in Mysore are the most essential construction materials for any building project, whether residential, commercial, or industrial. As a trusted construction material supplier in Mysore, we provide high-quality bricks and sand tailored to your project’s specific needs—from foundation to finish. We offer a wide range of products, including red bricks, fly ash bricks, M-Sand, river sand, and more, all delivered on time and at competitive prices. Whether you’re building a home or managing a large construction site, we ensure reliable supply, quality assurance, and expert support. Choose us for the best Bricks & Sand in Mysore.

Table of Contents

- Introduction: Bricks & Sand in Mysore – Our Promise

- Why Choose Us as Your Bricks & Sand Supplier in Mysore

- Types of Bricks We Supply in Mysore

3.1 Burnt Clay / Red Bricks

3.2 Fly Ash Bricks

3.3 Concrete Bricks & Blocks

3.4 Sand‑Lime (Calcium Silicate) Bricks

3.5 Engineering Bricks & Refractory / Fire Bricks

3.6 Hollow Bricks, Perforated & Interlocking Bricks - Types of Sand We Supply in Mysore

4.1 River Sand / Natural Sand

4.2 M‑Sand / Manufactured Sand

4.3 Plastering Sand / Fine Sand

4.4 Pit Sand

4.5 Quarry Sand / Gravel Mix - How to Choose the Right Brick & Sand for Your Project

- Quality Assurance, Testing & Delivery in Mysore

- Our Construction Materials Range: From Foundation to Finish

- Frequently Asked Questions (FAQ)

- Conclusion / Call to Action

1. Introduction: Bricks & Sand in Mysore – Our Promise

Bricks & Sand in Mysore is more than just a phrase — it’s our core service promise. As a leading construction materials supplier in Mysore, we deliver all kinds of bricks and sand, tailored to every phase of your building project. Whether you are laying the foundation, erecting walls, doing plastering or finishing work — we’ve got you covered.

From the very first words, “Bricks & Sand in Mysore” appears to maximize SEO relevance.

In this article, you will learn:

- What types of bricks and sand we stock

- How to choose the right materials for your structure

- How we ensure quality — and how we deliver across Mysore

- Some technical tips and external resources for deeper understanding

2. Why Choose Us as Your Bricks & Sand Supplier in Mysore

As a full‑spectrum construction materials supplier in Mysore, we offer these advantages:

- Comprehensive range: not just bricks & sand, but also cement, aggregates, steel, blocks, finishes — everything from foundation to finish.

- Local presence & delivery: We understand Mysore’s logistics, permitting quick and cost‑effective transport across city zones and outskirts.

- Quality checks & testing: We test brick compressive strength, water absorption, sand gradation, moisture content, etc.

- Bulk supply & flexibility: You can get large construction‑site deliveries or smaller quantities for individual residential works.

- Technical support & guidance: We help clients choose the right materials for walls, structural elements, or aesthetic finishes.

- Transparent pricing & sourcing: We work with brick kilns, crushers, sand pits, and we pass the cost benefits to you.

When your customer or contractor searches “Bricks & Sand in Mysore”, we want this page to be their first choice — both for trust and technical value.

3. Types of Bricks We Supply in Mysore

We supply all major types of bricks, suited for different structural and non‑structural purposes. Below is a breakdown:

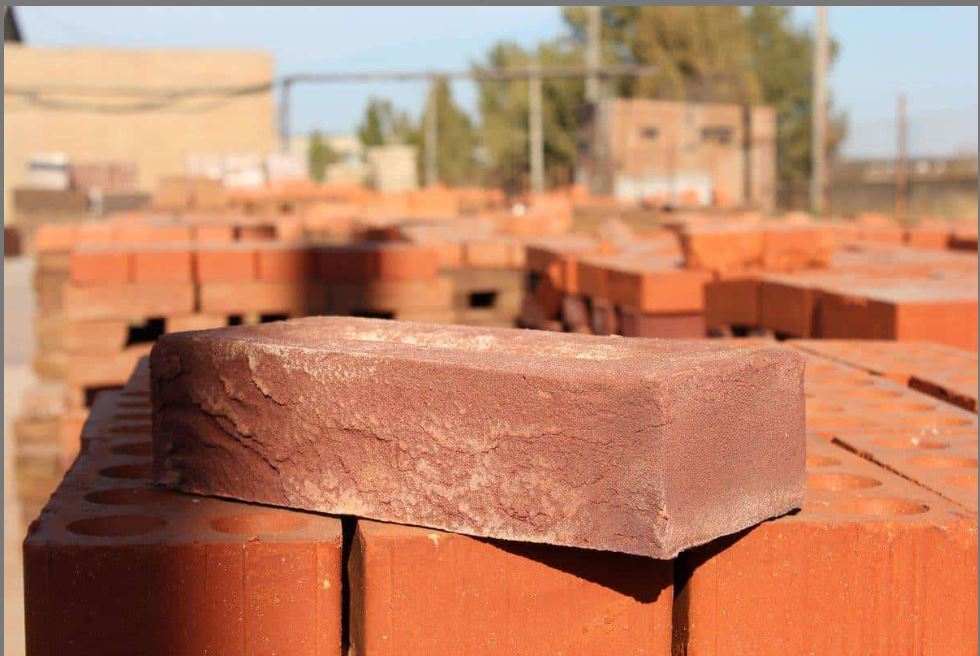

3.1 Burnt Clay / Red Bricks

This is the traditional, most common brick type. Made from clay, shaped, and fired in kilns, burnt clay bricks are durable and widely used.

Grades / classes:

- First class bricks (best quality, low voids, uniform shape)

- Second / third class (for non‑critical walls)

Use cases: load‐bearing walls, partition walls, external walls.

3.2 Fly Ash Bricks

Fly ash bricks are made using fly ash (a by‑product of coal combustion), cement, and water. They are lightweight, uniform, and more eco‑friendly.

Advantages:

- Less weight → lower dead load

- Uniform shape → less mortar usage

- Good compressive strength

- Better insulation properties

These are ideal for residential and commercial walling where lighter load is desired.

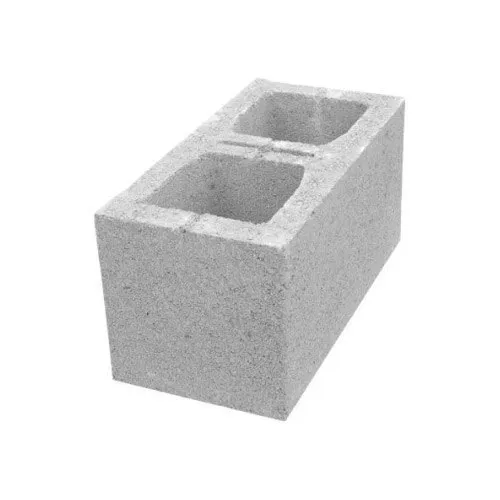

3.3 Concrete Bricks & Blocks

Concrete bricks are made from cement, sand, and coarse aggregate.

Variants:

- Solid concrete bricks

- Hollow concrete blocks

- Paving bricks

They are good for façade work, fence walls, and sometimes structural elements in combination with reinforced concrete.

3.4 Sand‑Lime (Calcium Silicate) Bricks

Also known as calcium silicate bricks, these are made by mixing sand, lime and sometimes fly ash under high pressure, and then curing them chemically.

They offer a smoother surface, good acoustic insulation, and are used in load‑bearing walls where aesthetics and uniform texture matter.

3.5 Engineering Bricks & Refractory / Fire Bricks

Engineering bricks are high‑density bricks with low water absorption and high strength. They’re used in load critical zones, basements, or areas exposed to moisture.

Fire bricks / refractory bricks are for special purposes – they can withstand high temperatures and are used in chimneys, furnaces, fireplaces, etc.

3.6 Hollow Bricks, Perforated & Interlocking Bricks

- Hollow bricks have cavities (voids) to reduce weight and provide insulation.

- Interlocking bricks are designed to lock together, reducing mortar joints and speeding up construction.

- Perforated / perforated bricks reduce material usage and weight.

These are increasingly popular in modern, efficient construction systems.

4. Types of Sand We Supply in Mysore

Just like bricks, sand comes in many grades. Here is what we offer under Bricks & Sand in Mysore:

4.1 River Sand / Natural Sand

This is the traditional sand sourced from rivers or riverbeds. It is well‑graded, has good particle shape, and is used in concrete, masonry, etc. Needs proper washing to remove silt.

4.2 M‑Sand / Manufactured Sand

M‑Sand is crushed rock sand produced by crushing hard granite, basalt or other stones in a crusher. It is an alternative to river sand where river sand is scarce or regulated.

It is well-graded, angular, and often cost‑effective if sourced near your site.

4.3 Plastering Sand / Fine Sand

This is finer sand (smaller particle size), ideal for plastering, masonry pointing, or smooth finishes where you need a fine scratch coat.

4.4 Pit Sand

Pit sand is coarse sand obtained from river pits. It has angular grains and is ideal for concrete work (foundation, structural concrete) due to its rough texture.

4.5 Quarry Sand / Gravel Mix

Sometimes we supply a mix of sand and small aggregates (chips) or sand obtained near crushing yards (quarry sand), which is slightly coarser but useful in some concrete and leveling works.

Each sand type is tested for grading / sieve analysis, fineness modulus, moisture content, and silt/clay content before supply.

5. How to Choose the Right Brick & Sand for Your Project

Selecting the right materials is critical. Here are guidelines:

- Structural vs non‑structural: For load bearing walls use first class clay bricks, fly ash bricks or engineering bricks. For partition walls or non‑load areas, hollow bricks or interlocking bricks may suffice.

- Moisture & water exposure: Use low water absorption bricks (engineering bricks) or waterproof treatments in damp zones.

- Thermal & acoustic insulation: Hollow bricks, fly ash bricks, and sand‑lime bricks often perform better.

- Mortar compatibility: Finer sand for plastering, coarser sand for concrete. The brick and sand combination should match the mortar strength you plan (e.g., 1:6, 1:4, etc.).

- Budget vs performance: Fly ash or M‑Sand might reduce cost in some projects.

- Aesthetics: If façade or exposed brickwork is involved, select bricks with uniform color, smooth finish, or special textures.

- Local availability & delivery cost: Always consider transport cost from brick kilns or sand pits to your Mysore project site.

For deeper reference on brick selection, you can check the JK Cement blog on “Different Types of Bricks”. JK Cement

6. Quality Assurance, Testing & Delivery in Mysore

We adhere to strict quality protocols:

- Brick testing: compressive strength test, water absorption (ideally ≤ 20 %), efflorescence, dimensional accuracy.

- Sand testing: sieve analysis to check gradation, fineness modulus (FM), silt/clay content, moisture content.

- Sampling & certificates: For large orders, we provide test certificates and sample bricks/sand.

- Packaging & transport: We stack bricks on pallets, wrap with protective sheets, and deliver via covered trucks.

- Delivery zones: We cover central Mysore, suburbs, and outskirts (e.g. Nanjangud road, Hunsur road, Periyapatna, etc.).

- Timely supply: We maintain buffer stock for popular bricks & sand grades.

- Return / breakage policy: We accept a small percentage of breakage (e.g. up to 2 %) for large deliveries, per industry norms.

7. Our Construction Materials Range: From Foundation to Finish

While this post is focused on Bricks & Sand in Mysore, we supply a full range:

- Cement (PPC, OPC)

- Steel / TMT bars

- Aggregates / Blue metal / Chips

- Blocks (AAC, concrete blocks)

- Tiles, flooring, roofing materials

- Plaster, paints, finishes

You can link internally to your pages on cement supply in Mysore, steel supply Mysore, or blocks & tiles Mysore (internal links).

For example:

“Check our Cement Supply in Mysore page for current rates and availability.”

“We also offer AAC Blocks in Mysore as a lightweight block option for walls.”

(You can replace text with actual internal URLs on your site.)

8. Frequently Asked Questions (FAQ)

Q1: Which is better, river sand or M‑Sand?

A1: River sand is natural and has rounded grains, which improves workability. But M‑Sand is more consistent, sustainable, and often cheaper if delivered locally. Use well‑graded M‑Sand to match performance.

Q2: Do I need to soak bricks before use?

A2: For traditional clay bricks, soaking helps reduce suction and avoids “drying out” mortar. Fly ash bricks may require only light sprinkling. Always follow manufacturer guidelines.

Q3: Can I use hollow bricks for load bearing walls?

A3: Only if the hollow brick is designed for load bearing (with specified compressive strength). Otherwise use solid bricks or reinforced block systems.

Q4: What is the ideal fineness modulus (FM) of sand for concrete?

A4: Typically FM between 2.3 to 3.0 is acceptable for general concrete. Very fine or very coarse sand may need blending.

Q5: How many bricks per square meter?

A5: With mortar joints, about 50–55 first class bricks per square meter for a single layer wall. (Depends on brick size and joint thickness.)

9. Conclusion / Call to Action

Bricks & Sand in Mysore isn’t just a keyword—it’s the foundation of what we do every day. We take pride in being a trusted supplier across Mysore for all your brick and sand needs, with high quality, prompt delivery, technical guidance, and full support from foundation to finish.

If you are planning a new construction, renovation, or even small masonry work, contact us for your Bricks & Sand in Mysore requirement. Let us provide you a quote, sample, or site visit — we are ready to partner with you in building something strong and lasting.

We will never break your trust like others do